BK101

Knowledge Base

3D Printing

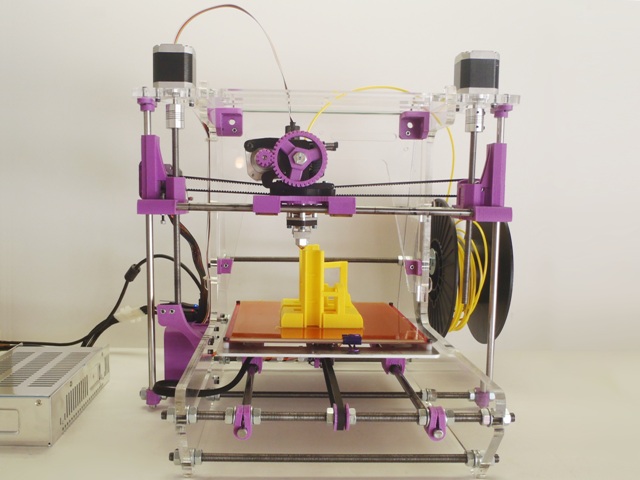

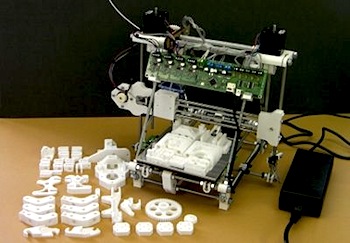

3D Printing is also known as additive manufacturing, refers to various processes used to synthesize a three-dimensional object. In three d printing, successive layers of material are formed under computer control to create an object. These objects can be of almost any shape or geometry and are produced from a 3D Model or other electronic data source. A 3D printer is a type of industrial robot.

3D Scanner is a device that analyses a

real-world object or environment to collect data on its shape and possibly

its appearance (e.g. colour). The collected data can then be used to

construct digital three-dimensional models.

2D.

3D Scanner is a device that analyses a

real-world object or environment to collect data on its shape and possibly

its appearance (e.g. colour). The collected data can then be used to

construct digital three-dimensional models.

2D.3D Modeling is the process of developing a mathematical representation of any three-dimensional surface of an object, either inanimate or living, via specialized software.

3D Printing Processes available tend to be additive in nature with a few key differences in the technologies and the materials used in this process. Some of the different types of physical transformations which are used in 3D printing include melt extrusion, light polymerization, continuous liquid interface production and sintering.

3D Printing (video)

Prototype - Design Software - Molding - Engineering - Body Parts

3-D Printing offers new approach to making Buildings. Technology developed at MIT could enable faster, cheaper, more adaptable building construction. Brick Houses (Building Blocks). 3D House Concrete Printer.

3D Light Printer - 3D Printing with Light

3D Printing is not a disruptive innovation, it's more of a productive innovation that offers more options and more convenience. 3D printing is like small farms. Small farms make a big difference, but not in the same way as big farms do. We need small farms, but we also need some big farms too.

Volumetric Printing is a three-dimensional digital-to-physical imaging technology developed in 2013 that uses ink or other pigments suspended in a volume to form a full-color volumetric scene in physical space. It is a static version of volumetric display. Volumetric prints are auto-stereoscopic, full parallax (in both horizontal and vertical viewing arrangements) and can be viewed by multiple viewers in regular room lighting. A volumetric print can be thought of as a reconstructed light field based on the scattering of light by distributed pigments in volume. Any three-dimensional scene can be volumetrically printed, although biological specimens and volumetrically X-rayed objects (i.e., CT scans) are thought to be particularly well suited to this type of imaging. There are several methods for producing a volumetric print, the most common being an index-matched stack of hundreds of sheets of thin clear material (most often PMMA, also known as Lucite or acrylic). Each sheet in the volumetric stack is printed with a color slice of a digital 3D model, placed in a vacuum chamber, and then injected with a fluid matching the index of refraction of the sheet material. Volumetric printing has been called "Hologram 2.0" by a company marketing the technology. Volumetric prints however are not produced in the same manner as holograms, in that there is no interference pattern generated or used in basic volumetric prints.

Topology Optimization is a mathematical method that optimizes material layout within a given design space, for a given set of loads, boundary conditions and constraints with the goal of maximizing the performance of the system. TO is different from shape optimization and sizing optimization in the sense that the design can attain any shape within the design space, instead of dealing with predefined configurations. The conventional TO formulation uses a finite element method (FEM) to evaluate the design performance. The design is optimized using either gradient-based mathematical programming techniques such as the optimality criteria algorithm and the method of moving asymptotes or non gradient-based algorithms such as genetic algorithms. Topology Optimization has a wide range of applications in aerospace, mechanical, bio-chemical and civil engineering. Currently, engineers mostly use TO at the concept level of a design process. Due to the free forms that naturally occur, the result is often difficult to manufacture. For that reason the result emerging from TO is often fine-tuned for manufacturability. Adding constraints to the formulation in order to increase the manufacturability is an active field of research. In some cases results from TO can be directly manufactured using additive manufacturing; TO is thus a key part of design for additive manufacturing.

Shape Optimization is part of the field of optimal control theory. The typical problem is to find the shape which is optimal in that it minimizes a certain cost functional while satisfying given constraints. In many cases, the functional being solved depends on the solution of a given partial differential equation defined on the variable domain.

Voxel represents a value on a regular grid in three-dimensional space. As with pixels in a 2D bitmap, voxels themselves do not typically have their position (i.e. coordinates) explicitly encoded with their values. Instead, rendering systems infer the position of a voxel based upon its position relative to other voxels (i.e., its position in the data structure that makes up a single volumetric image). In contrast to pixels and voxels, polygons are often explicitly represented by the coordinates of their vertices (as points). A direct consequence of this difference is that polygons can efficiently represent simple 3D structures with much empty or homogeneously filled space, while voxels excel at representing regularly sampled spaces that are non-homogeneously filled. Voxels are frequently used in the visualization and analysis of medical and scientific data (e.g. GIS). Some volumetric displays use voxels to describe their resolution. For example, a cubic volumetric display might be able to show 512×512×512 voxels. The word voxel originated analogously to the word "pixel", with vo representing "volume" and el representing "element"; similar formations with el for "element" include the words "pixel" and "texel". One of the definitions is: "Voxel is an image of a three-dimensional space region limited by given sizes, which has its own nodal point coordinates in an accepted coordinate system, its own form, its own state parameter that indicates its belonging to some modeled object, and has properties of modeled region." This definition has the following advantage. If fixed voxel form is used within the whole model it is much easier to operate with voxel nodal points, i.e. three coordinates of this point. Yet, there is the simple form of record – indexes of the elements in the model set, i.e. integer coordinates. Model set elements in this case are state parameters, indicating voxel belonging to the modeled object or its separate parts, including their surfaces.

Boundary Value Problem is a differential equation together with a set of additional constraints, called the boundary conditions. A solution to a boundary value problem is a solution to the differential equation which also satisfies the boundary conditions.

Overprinting refers to the process of printing one color on top of another in reprographics. This is closely linked to the reprographic technique of 'trapping'. Another use of overprinting is to create a rich black (often regarded as a colour that is "blacker than black") by printing black over another dark colour.

Reprography is the reproduction of graphics through mechanical or electrical means, such as photography or xerography. Reprography is commonly used in catalogs and archives, as well as in the architectural, engineering, and construction industries.

Comparative study of gelatin methacrylate hydrogels from different sources for biofabrication applications.

The King of 3D printing materials? Polymaker PolyMax PC REVIEW (youtube)

Polycarbonate are a group of thermoplastic polymers containing carbonate groups in their chemical structures. Polycarbonates used in engineering are strong, tough materials, and some grades are optically transparent. They are easily worked, molded, and thermoformed. Because of these properties, polycarbonates find many applications. Polycarbonates do not have a unique resin identification code (RIC) and are identified as "Other", 7 on the RIC list. Upper working temperature: 115–130 °C (239–266 °F) / Lower working temperature: -40 °C (-40 °F) / Linear thermal expansion coefficient (a): 65–70 × 10-6/K / Heat deflection temperature: 0.45 MPa: 140 °C (284 °F); 1.8 MPa: 128–138 °C (262–280 °F) / Thermal conductivity (k) at 23 °C: 0.19–0.22 W/(m·K).

3D Print File Extension: STL Files are a standard file type that interfaces between Computer Aided Design (CAD) software and 3D printers. OBJ is an open file format that represents 3D geometry. VRML (or WRL) files are commonly used when a 3D model has color and you want to transfer that color to the print.

One Off is something that is created only once, and often quickly, simply, or improvisationally. Occurring once, one-time, independent of any pattern. Being singular, unique and special.

Carbon 3D - New Type of 3D Printing.

uArm Swift: Your Personal Robotic Assistant

Stepper Motor is a brushless DC Electric Motor that divides a full rotation into a number of equal steps. The motor's position can then be commanded to move and hold at one of these steps without any feedback sensor (an open-loop controller), as long as the motor is carefully sized to the application in respect to torque and speed. Switched reluctance motors are very large stepping motors with a reduced pole count, and generally are closed-loop commutated.

Highest throughput 3D printer is the future of manufacturing. Rapid manufacturing on-demand could make parts-warehousing and expensive molds a thing of the past. Researchers have developed a new, futuristic 3D printer that is so big and so fast it can print an object the size of an adult human in just a couple of hours. The prototype HARP technology is 13-feet tall with a 2.5 square-foot print bed and can print about half a yard in an hour -- a record throughput for the 3D printing field. This means it can print single, large parts or many different small parts at once.

New high-speed microscale 3D printing technique. A new process for microscale 3D printing creates particles of nearly any shape for applications in medicine, manufacturing, research and more -- at the pace of up to 1 million particles a day.

Printing tiny, high-precision objects in a matter of seconds (youtube) - Researchers at EPFL have developed a new, high-precision method for 3D-printing small, soft objects.

Avoiding Defects during Additive Manufacturing. Research reveals how pores form during metals additive manufacturing and become defects trapped in solidifying metal. The practical value of this research is that it can inform industry on how to predict and improve 3D printing processes. Laser powder bed fusion is a dominant additive manufacturing technology that has yet to reach its potential. The problem facing industry is that tiny bubbles or pores sometimes form during the printing process, and these pores create weak spots in finished products.

New 3D-printing method makes printing objects more affordable and eco-friendly.

Additive manufacturing Algorithms Making new technology faster and cheaper. The software's algorithm automatically determines a part's sections and the sections' orientations. From this, the software designates when each section will be printed, and in which orientation within the printing sequence. The algorithm can help inform a designer's process plan to manufacture a part. It allows designers opportunities to make corrections or alter the design before printing, which can positively affect cost. The algorithm can also inform a designer how feasible a part may be to create using support-free manufacturing.

New 3D printing process is faster and more precise than conventional methods. Engineers have created a way to 3D print large and complex parts at a fraction of the cost of current methods. The new approach, called Multiplexed Fused Filament Fabrication or MF3, uses a single gantry, the sliding structure on a 3D printer, to print individual or multiple parts simultaneously. By programming their prototype to move in efficient patterns, and by using a series of small nozzles - rather than a single large nozzle, as is common in conventional printing - to deposit molten material, the researchers were able to increase printing resolution and size as well as significantly decrease printing time. The 3D-printing industry has struggled with what is known as the throughput-resolution tradeoff - the speed at which 3D printers deposit material versus the resolution of the finished product. Larger-diameter nozzles are faster than smaller ones but generate more ridges and contours that must be smoothed out later, adding significant post-production costs. By contrast, smaller nozzles deposit material with greater resolution, but current methods with conventional software are too slow to be cost effective. At the heart of MF3's innovation is its software. To program a 3D printer, engineers use a software tool called a slicer - computer code that maps an object into the virtual "slices," or layers, that will be printed. Rutgers researchers wrote slicer software that optimized the gantry arm's movement and determined when the nozzles should be turned on and off to achieve the highest efficiency. MF3's new "toolpath strategy" makes it possible to "concurrently print multiple, geometrically distinct, non-contiguous parts of varying sizes" using a single printer, the researchers wrote in their study.

3D-printed material to replace ivory. A new material called 'Digory' has been developed, which can be processed in 3D printers and is extremely similar to ivory. It can be used to restore old ivory artifacts.

Why 3D Printing Batteries Matters (youtube) - Solid State Batteries.

3D printed nanomagnets unveil a world of patterns in the magnetic field. Researchers have created DNA-like magnetic nanostructures that form strong inter-helix magnetic bonds. These produce topological textures in the magnetic field, opening the door to the next generation of magnetic devices, and patterning magnetic fields on the nanoscale.

Nanomaterials: 3D printing of glass without sintering. A new process enables printing of nanometer-scale quartz glass structures directly onto semiconductor chips. A hybrid organic-inorganic polymer resin is used as feedstock material for 3D printing of silicon dioxide. Since the process works without sintering, the required temperatures are significantly lower. Simultaneously, increased resolution enables visible-light nanophotonics.

Algorithm learns to correct 3D printing errors for different parts, materials and systems. Engineers have created intelligent 3D printers that can quickly detect and correct errors, even in previously unseen designs, or unfamiliar materials like ketchup and mayonnaise, by learning from the experiences of other machines.

3D-printed revolving devices can sense how they are moving. Researchers created a system that enables makers to incorporate sensors directly into rotational mechanisms with only one pass in a 3D printer. This gives rotational mechanisms like gearboxes the ability to sense their angular position, rotation speed, and direction of rotation. Integrating sensors into rotational mechanisms could make it possible for engineers to build smart hinges that know when a door has been opened, or gears inside a motor that tell a mechanic how fast they are rotating. MIT engineers have now developed a way to easily integrate sensors into these types of mechanisms, with 3D printing.

Researchers 3D print sensors for satellites. Cheap and quick to produce, these digitally manufactured plasma sensors could help scientists predict the weather or study climate change. Researchers demonstrated a 3D-printed plasma sensor for satellites that works just as well as the expensive semiconductor sensors that take weeks of intricate fabrication in a cleanroom. These durable, precise sensors could be used on CubeSats, which are commonly utilized for environmental monitoring or weather prediction. These plasma sensors, also known as retarding potential analyzers (RPAs), are used by satellites to determine the chemical composition and ion energy distribution of the atmosphere.

Metal 3D Printing

How Metal 3D Printing Works (youtube)

3D Printing Metal in Midair (youtube)

Markforge Metal x 3D Printer

Desktop Metal 3D metal printing systems from prototyping to mass production.

Metal 3D Printing Systems for the full product life cycle – from prototyping to mass production.

Atomized Metal Powders, or Powder Metallurgy for Additive Manufacturing.

The Largest Metal 3D Printer in the world. Built for rockets.

3D Printing from 2D Objects

Photogrammetry is the art and science of making measurements from photographs, especially for recovering the exact positions of surface points. Photogrammetric analysis may be applied to one photograph, or may use high-speed photography and remote sensing to detect, measure and record complex 2-D and 3-D motion fields by feeding measurements and imagery analysis into computational models in an attempt to successively estimate, with increasing accuracy, the actual, 3-D relative motions. From its beginning with the stereoplotters used to plot contour lines on topographic maps, it now has a very wide range of uses such as sonar, radar, and lidar.

Stereoplotter uses stereo photographs to determine elevations. It has been the primary method to plot contour lines on topographic maps since the 1930s.

Stereo-Lithography is a form of 3-D printing technology used for creating models, prototypes, patterns, and production parts in a layer by layer fashion using photopolymerization, a process by which light causes chains of molecules to link together, forming polymers, which are large molecules, or macromolecules, composed of many repeated subunits.

HARP or High-Area Rapid Printing, is a new technology that enables a record-breaking throughput that can manufacture products on demand. This means it can print single, large parts or many different small parts at once.

Computed Axial Lithography is a method for 3D printing based on computerized tomography scans to create objects from photo-curable resin. Computed axial lithography does not build models through depositing layers of material, as fused deposition modelling and stereolithography does, instead it creates objects using a series of 2D images projected onto a cylinder of resin. It is notable for its ability to build object much more quickly than other methods using resins and the ability to embed objects within the objects.

Image Plane is that plane in the world which is identified with the plane of the display monitor used to view the image that is being rendered. It is also referred to as screen space. If one makes the analogy of taking a photograph to rendering a 3D image, the surface of the film is the image plane. In this case, the viewing transformation is a projection that maps the world onto the image plane. A rectangular region of this plane, called the viewing window or viewport, maps to the monitor. This establishes the mapping between pixels on the monitor and points (or rather, rays) in the 3D world. The plane is not usually an actual geometric object in a 3D scene, but instead is usually a collection of target coordinates or dimensions that are used during the rasterization process so the final output can be displayed as intended on the physical screen. In optics, the image plane is the plane that contains the object's projected image, and lies beyond the back focal plane.

Graphics Pipeline is a conceptual model that describes what steps a graphics system needs to perform to render a 3D scene to a 2D screen.

Projection Plane is a type of view in which graphical projections from an object intersect. Projection planes are used often in descriptive geometry and graphical representation. A picture plane in perspective drawing is a type of projection plane. With perspective drawing, the lines of sight, or projection lines, between an object and a picture plane return to a vanishing point and are not parallel. With parallel projection the lines of sight from the object to the projection plane are parallel.

Parallel Projection is a projection of an object in three-dimensional space onto a fixed plane, known as the projection plane or image plane, where the rays, known as lines of sight or projection lines, are parallel to each other. It is a basic tool in descriptive geometry. The projection is called orthographic if the rays are perpendicular (orthogonal) to the image plane, and oblique or skew if they are not.

Magic with D Printer! (youtube) - Have you ever wondered if a model can be created from an Image? In this video, you will see it actually happen using 3D Printing process right from the design to end product.

Cool Things that can be 3D Printed

3D Printed Glass. 3D printing of chalcogenide glass could enable low-cost manufacturing of complex optical components for telecom and sensing applications. Chalcogenide Glass is a glass containing one or more chalcogens (sulfur, selenium and tellurium, but excluding oxygen). Such glasses are covalently bonded materials and may be classified as covalent network solids. Polonium is also a chalcogen but is not used because of its strong radioactivity. Chalcogenide materials behave rather differently from oxides, in particular their lower band gaps contribute to very dissimilar optical and electrical properties.

MIT 3D Print With Glass (video)

3-D Printed Polymer turns Methane to Methanol

eora 3D - High-precision 3D Scanning

Borromean Hairpins (youtube)

AxiDraw V3 Robotic Pen (video)

Velikonocni prani - EggBot - Happy Easter (youtube)

Smart Ink adds New Dimensions to 3-D Printing. New smart ink turns 3-D-printed structures into objects that can change shape and color.

Scientists Print All-Liquid 3-D Structures. Reconfigurable material could be used for liquid electronics and chemical synthesis, among other applications.

3-D Imaging of Excited Quantum Dots.

Cheap 3-D Printer can produce Self-Folding Materials.

3-D Printing of Millimeter-sized Imaging Lenses. The method could impact optical imaging, vision correction, and disease diagnosis. Fabricating Optically Active Structures - Advanced Materials.

3D Printed Tires and Shoes that Self-Repair. The material is

manufactured using a 3D printing method that uses photopolymerization.

This process uses light to solidify a liquid resin in a desired shape or

geometry. To make it

self-healable, they had to dive a little deeper into the chemistry

behind the material.

Photopolymerization is achieved through a reaction with a certain

chemical group called

thiols.

By adding an oxidizer to the equation, thiols transform into another group

called disulfides. It is the disulfide group that is able to reform when

broken, leading to the self-healing ability. Finding the right ratio

between these two groups was the key to unlocking the materials' unique

properties. When we gradually increase the

oxidant, the self-healing

behavior becomes stronger, but the photopolymerization behavior becomes

weaker. In just 5 seconds, they can print a 17.5-millimeter square,

completing whole objects in around 20 minutes that can repair themselves

in just a few hours. After being cut in half, in just two hours at 60

degrees Celsius (four for the electronics due to the carbon used to

transmit electricity) they healed completely, retaining their strength and

function. The repair time can be decreased just by raising the

temperature. We actually show that under different temperatures -- from 40

degrees Celsius to 60 degrees Celsius -- the material can heal to almost

100 percent.

3D Printed Tires and Shoes that Self-Repair. The material is

manufactured using a 3D printing method that uses photopolymerization.

This process uses light to solidify a liquid resin in a desired shape or

geometry. To make it

self-healable, they had to dive a little deeper into the chemistry

behind the material.

Photopolymerization is achieved through a reaction with a certain

chemical group called

thiols.

By adding an oxidizer to the equation, thiols transform into another group

called disulfides. It is the disulfide group that is able to reform when

broken, leading to the self-healing ability. Finding the right ratio

between these two groups was the key to unlocking the materials' unique

properties. When we gradually increase the

oxidant, the self-healing

behavior becomes stronger, but the photopolymerization behavior becomes

weaker. In just 5 seconds, they can print a 17.5-millimeter square,

completing whole objects in around 20 minutes that can repair themselves

in just a few hours. After being cut in half, in just two hours at 60

degrees Celsius (four for the electronics due to the carbon used to

transmit electricity) they healed completely, retaining their strength and

function. The repair time can be decreased just by raising the

temperature. We actually show that under different temperatures -- from 40

degrees Celsius to 60 degrees Celsius -- the material can heal to almost

100 percent.Magnetic 3D-Printed structures crawl, roll, and jump. New printing technique could be used to develop remotely controlled biomedical devices, a spider-like 'grabber' that can crawl, roll, jump, and snap together fast enough to catch a passing ball.

Flexible Circuits for 3D Printing. A research cooperation has developed a process suitable for 3D printing that can be used to produce transparent and mechanically flexible electronic circuits. The technique can enable new applications such as printable light-emitting diodes, solar cells or tools with integrated circuits, as the scientists report in the journal Scientific Reports. The researchers are demonstrating the potential of their process with a flexible capacitor, among other things.

3D-printed plastics with high performance electrical circuits. Innovation could lead to better drones, satellites, biomedical devices.

M3D Pro: Feature-Packed 3D Printer for Reliability. Professional 3D Printer that bridges the gap between power users and consumers.

Fast Radius - Big Rep - 3D Printing Industry News

New 4-D Printer could one day allow manufacturers to produce electronic devices and their wiring in a single process.

3D printing can now manufacture customized sensors for robots, pacemakers, and more. A newly-developed 3D printing technique could be used to cost-effectively produce customized electronic 'machines' the size of insects which enable advanced applications in robotics, medical devices and others. The breakthrough could be a potential game-changer for smaller volume manufacturing of customized chip-based microelectromechanical systems or MEMS.

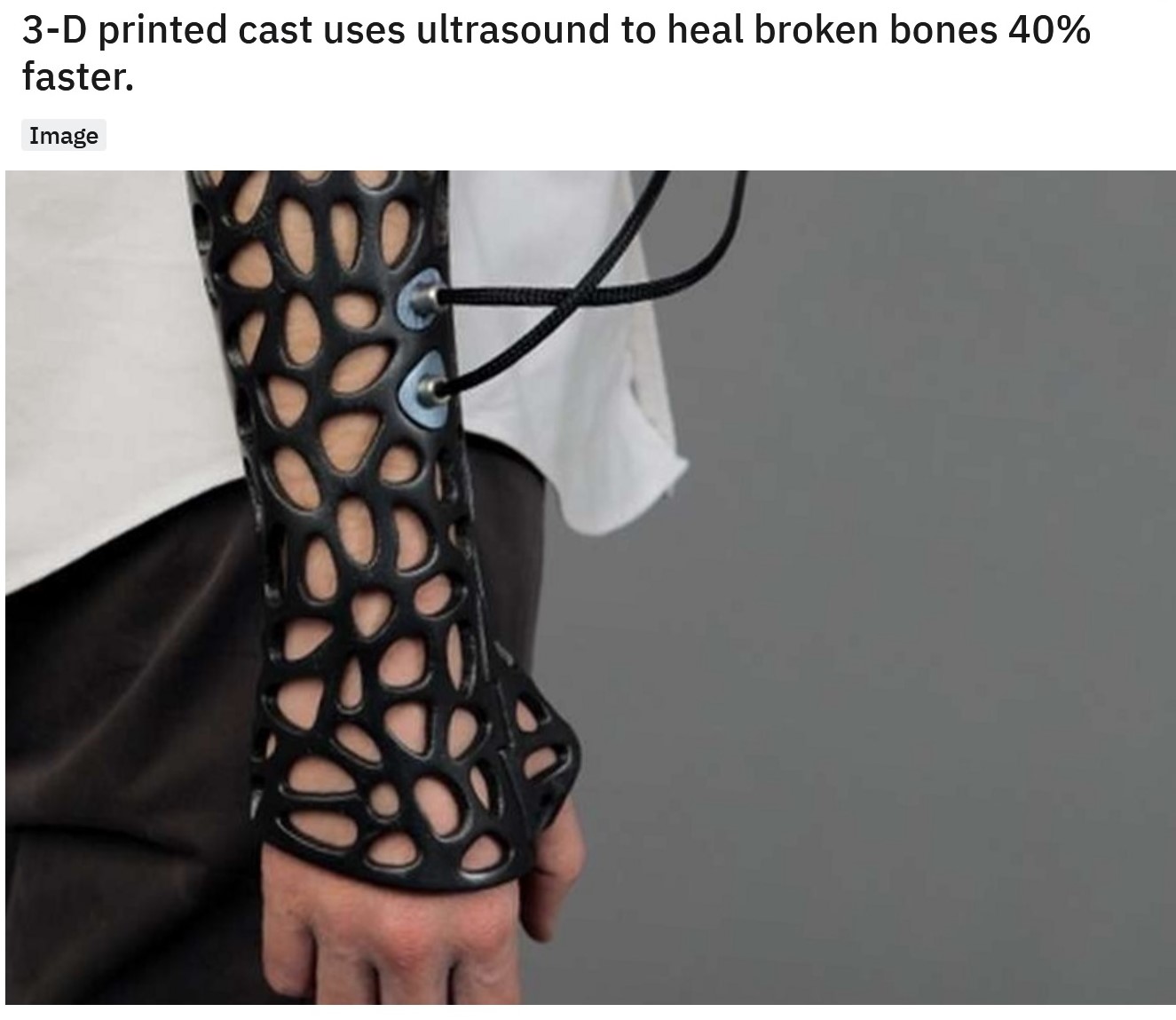

3-D Printed Body Parts

3D Bioprinting is the process of creating cell patterns in a confined space using 3D printing technologies, where cell function and viability are preserved within the printed construct. Generally, 3D bioprinting utilizes the layer-by-layer method to deposit materials known as Bioinks create tissue-like structures that are later used in medical and tissue engineering field. Bioprinting covers a broad range of materials. Currently, bioprinting can be used to print tissues and organs to help research drugs and pills. In addition, 3D bioprinting has begun to incorporate the printing of scaffolds. These scaffolds can be used to regenerate joints and ligaments. The first patent related to this technology was filed in the United States in 2003 and granted in 2006. 3D Bioprinting is the manufacturing of tissue or organ models by printing hydrogel seeded with live cells. Compared to non-biological printing, 3D bioprinting is more complex due to the choice of materials, cell types, growth and differentiation factors, and technical challenge related to the sensitivity of living cells and the complexities of functional tissues/organs. In-Vitro.

3D Bioprinted Human Cartilage Cells can be Implanted - Robotics (surgery)

3D Printing of Living Cells using a new technique they call ‘in-air microfluidics’. Microfluidics is all about manipulating tiny drops of fluid with sizes between a micrometer and a millimeter.

3-D Printed Body Parts. 3-D printed microfibers could provide structure for artificially grown body parts. Stem-cell-loaded hydrogels reinforced with fibers like the rebar in cement can grow living cells in defined patterns and eventually the fibers will dissolve and go away. If we could multiplex electrospinning with a collagen gel and bioprinting, we could build large and complex tissue interfaces, such as bone to cartilage. Low-cost and efficient method to fabricate high-resolution and repeatable 3-D polymer fiber patterns on nonconductive materials for tissue engineering with available hobbyist-grade 3-D printers. The method they use is a combination of 3-D printing and electrospinning, a method that uses electric charge to spin nanometer threads from either a polymer melt or solution. printer can deposit a precise pattern of fibers in three dimensions to form a scaffold in a hydrogel on which cells can grow. Once the tissue has grown sufficiently, the scaffolding can be dissolved, leaving only a structured tissue appropriate for use. If two different tissues -- muscle and tendon -- are needed, the 3-D printer can alter the pattern of threads in such a way that the transition could be seamless with the appropriate cells, resulting in a naturally formed, two-part tissue replacement.

Organ Bioprinting gets a breath of fresh air. Bioengineers have cleared a major hurdle on the path to 3D printing replacement organs. It's a breakthrough technique for bioprinting tissues with exquisitely entangled vascular networks that mimic the body's natural passageways for blood, air, lymph and other vital fluids.

Scientists develop 3D printing method that shows promise for repairing brain injuries. Researchers have produced an engineered tissue representing a simplified cerebral cortex by 3D printing human stem cells. When implanted into mouse brain slices, the structures became integrated with the host tissue. The technique may ultimately be developed into tailored repairs to treat brain injuries.

Wound Healing - Self Healing Space Ships

3D Printed Ear. Researchers produce grafts that replicate the human ear. Using state-of-the-art tissue engineering techniques and a 3D printer, researchers have assembled a replica of an adult human ear that looks and feels natural. The study offers the promise of grafts with well-defined anatomy and the correct biomechanical properties for those who are born with a congenital malformation or who lose an ear later in life.

Bio-Ink are substances made of living cells that can be used for 3D printing of complex tissue models. Bioinks are materials that mimic an extracellular matrix environment to support the adhesion, proliferation, and differentiation of living cells. Bioinks distinguish themselves from traditional biomaterials such as hydrogels, polymer networks, and foam scaffolds due to their ability to be deposited as filaments during an additive manufacturing process. Additionally, unlike traditional additive manufacturing materials such as thermoplastic polymers, ceramics, and metals which require the use of harsh solvents, cross-linking modalities and high temperatures to be printed, bioinks are processed under much milder conditions. These mild conditions are necessary to preserve compatibility with living cells, and prevent degradation of bioactive molecules and macroproteins. These bioinks are often adopted from existing hydrogel biomaterials and derived from natural polymers such as gelatins, alginates, fibrin, chitosan, and hyaluronic acids that are sensitive to their processing conditions. Unlike the thermoplastics that are often utilized in traditional 3D printing, the chain entanglements and ionic interactions within the hydrogel-like bioink rather than temperature dominate shape fidelity. The natural derivation of many bioinks often results in a high water content and sensitivity to harsh processing conditions. Therefore, bioink filaments are often deposited at or below human body temperature and under mild conditions to preserve bioink printability. Additional considerations must be taken into account when printing bioinks blended with a cell suspension due to the need to preserve cell viability. Differences from traditional 3D printing materials. Printed at a much lower temperature (37 °C or below). Mild cross-linking conditions. Natural derivation. Bioactive. Cell manipulatable.

3-D Printing creates Super Soft Structures that Replicate Brain and Lungs.

Scientists Print first 3D Heart using patient's biological materials. Engineered heart completely matches the immunological, cellular, biochemical and anatomical properties of the patient.

New method promises advances in 3D printing, manufacturing and biomedical applications. Researchers have created a method to precisely create droplets using a jet of liquid. The technique allows manufacturers to quickly generate drops of material, finely control their size and locate them within a 3D space.

Engineered Tissue Folding by Mechanical Compaction of the Mesenchyme. Many tissues fold into complex shapes during development. Controlling this process in vitro would represent an important advance for tissue engineering. We use embryonic tissue explants, finite element modeling, and 3D cell-patterning techniques to show that mechanical compaction of the extracellular matrix during mesenchymal condensation is sufficient to drive tissue folding along programmed trajectories. The process requires cell contractility, generates strains at tissue interfaces, and causes patterns of collagen alignment around and between condensates. Aligned collagen fibers support elevated tensions that promote the folding of interfaces along paths that can be predicted by modeling. We demonstrate the robustness and versatility of this strategy for sculpting tissue interfaces by directing the morphogenesis of a variety of folded tissue forms from patterns of mesenchymal condensates. These studies provide insight into the active mechanical properties of the embryonic mesenchyme and establish engineering strategies for more robustly directing tissue morphogenesis ex vivo.

New Printing Technique uses cells and molecules to recreate Biological Structures.

New 3D Printer can create complex Biological Tissues.

Printed robots with bones, ligaments, and tendons. For the first time, researchers have succeeded in printing a robotic hand with bones, ligaments and tendons made of different polymers using a new laser scanning technique. The new technology makes it possible to 3D print special plastics with elastic qualities in one go. This opens up completely new possibilities for the production of soft robotic structures.

Infection-resistant, 3D-printed metals developed for implants. A novel surgical implant was able to kill 87% of the bacteria that cause staph infections in laboratory tests, while remaining strong and compatible with surrounding tissue like current implants. The work could someday lead to better infection control in many common surgeries, such as hip and knee replacements, that are performed daily around the world. Bacterial colonization of the implants is one of the leading causes of their failure and bad outcomes after surgery. Using 3D-printing technology, the researchers added 10% tantalum, a corrosion-resistant metal, and 3% copper to the titanium alloy typically used in implants. When bacteria come into contact with the material's copper surface, almost all of their cell walls rupture. Meanwhile, the tantalum encourages healthy cell growth with surrounding bone and tissue leading to expedited healing for the patient.

Electrospinning is a fiber production method which uses electric force to draw charged threads of polymer solutions or polymer melts up to fiber diameters in the order of some hundred nanometers. Electrospinning shares characteristics of both electrospraying and conventional solution dry spinning of fibers. The process does not require the use of coagulation chemistry or high temperatures to produce solid threads from solution. This makes the process particularly suited to the production of fibers using large and complex molecules. Electrospinning from molten precursors is also practiced; this method ensures that no solvent can be carried over into the final product.

3-DIY: Printing your own Bioprinter. Researchers have developed a low-cost 3-D bioprinter by modifying a standard desktop 3-D printer, and they have released the breakthrough designs as open source so that anyone can build their own system.

Researchers develop 3D printed objects that can track and store how they are used. Engineers have developed 3D printed devices that can track and store their own use -- without using batteries or electronics. Instead, this system uses a method called backscatter, through which a device can share information by reflecting signals that have been transmitted to it with an antenna.

Researchers 3D print key components for a point-of-care mass spectrometer. The low-cost hardware outperforms state-of-the-art versions and could someday enable an affordable, in-home device for health monitoring.

Backscatter is the reflection of waves, particles, or signals back to the direction from which they came. It is a diffuse reflection due to scattering, as opposed to specular reflection as from a mirror. Backscattering has important applications in astronomy, photography, and medical ultrasonography. The opposite effect is forward scatter, e.g. when a translucent material like a cloud diffuses sunlight, giving soft light.

Bio-Mimicry

3D Printed Braces

3D Printed Drugs - Print your own Medicine (video)

Scientists get soft on 3D printing. New method could jump-start creation of tiny medical devices for the body. Researchers at the National Institute of Standards and Technology (NIST) have developed a new method of 3D-printing gels and other soft materials. Published in a new paper, it has the potential to create complex structures with nanometer-scale precision. Because many gels are compatible with living cells, the new method could jump-start the production of soft tiny medical devices such as drug delivery systems or flexible electrodes that can be inserted into the human body.

3-D Print Electronics and Cells Printed directly on Skin. Print temporary sensors on the body to detect chemical or biological agents or solar cells to charge essential electronics. To remove the electronics, the person can simply peel off the electronic device with tweezers or wash it off with water.

Scientists bioprint tissue-like constructs capable of controlled, complex shape change. 4D constructs have the potential to mimic how tissues change shape in the body. New cell-laden bioink, comprised of tightly-packed, flake-shaped microgels and living cells, the production of cell-rich 4D bioconstructs that can change shape under physiological conditions. Where standard 3D printing uses a digital blueprint to manufacture an object out of materials like plastic or resin, 3D bioprinting manufactures biological parts and tissues out of living cells, or bioinks. A fourth dimension -- shape transformation over time -- can be achieved by incorporating materials that enable printed constructs to morph multiple times in a preprogrammed or on-demand manner in response to external signals.

Major step forward in biofabricating an artificial heart, fit for a human. By recreating the helical structure of heart muscles, researchers improve understanding of how the heart beats. Bioengineers have developed the first biohybrid model of human ventricles with helically aligned beating cardiac cells, and have shown that muscle alignment does, in fact, dramatically increases how much blood the ventricle can pump with each contraction. Heart disease -- the leading cause of death in the U.S. -- is so deadly in part because the heart, unlike other organs, cannot repair itself after injury. That is why tissue engineering, ultimately including the wholesale fabrication of an entire human heart for transplant, is so important for the future of cardiac medicine.

Guns 3D Printed

3D Printed Firearms or 3D printed Guns are plastic, but they still have metal parts. Metal screws or bullets sitting inside a much thicker steel shell are needed to absorb the majority of the force. So an effectively used Metal Detector might still work, but a pat down or hand search might be necessary, just Don't touch my junk. This is why educating people and informing the public is so extremely important, because ignorant people will always be vulnerable to doing ignorant things with technology.

Frisking is a search of a person's outer clothing wherein a person runs his or her hands along the outer garments to detect any concealed weapons.

Strip Search is a practice of searching a person for weapons or other contraband suspected of being hidden on their body or inside their clothing, and not found by performing a frisk search, by requiring the person to remove some or all of his or her clothing. TSA Rules.

Improvised Firearm is a firearm manufactured other than by a firearms manufacturer or a gunsmith, and is typically constructed by adapting existing materials to the purpose.

Untraceable Firearms or Ghost Gun is a firearm without serial numbers. By making the gun themselves or buying guns privately or second hand, owners may legally bypass background checks and registration regulations, the same way Arms Trafficking, Small Arms Trade and the Gun Show Loophole, which refers to the sale of firearms by private sellers, including those done at gun shows, that are exempt from federal background check requirements. This is dubbed the private sale exemption or "secondary market". Gun Control.

3D Printing Resources

Sustainable 3D Printer Filament

Sustainable 3D Printer FilamentObjet

Materialise

Replicat

Makerbot

Mcor Technologies

Shapeways

Sculpteo

D-Shape

Hubs Custom Parts

Big Rep Large Format 3D Printing.

Custom 3D Printing

Plastic Filament Maker

Rapide Desktop 3D Printer

3D Micro Printer

The MOD-t 3D Printer for Everyone

101Hero: The World's Most Affordable 3D Printer

Yeehaw 3D Printer for creative Kids - only $249

RoVa4D Full Color Blender FDM 3D Printer

3D Smartphone Controlled Game

Rapide Lite High Resolution 3D Printer

Continuous Liquid Interface Production

3D Printing by Hand

3D Design Studio

3D Simo

Maker Arm

Thingiverse 3D Modeling Program.

Makezine platform for connecting Makers.

Digital Habits interactive products.

Warick Manufacturing group 3D Printing

Polymaker

3D Phacktory

3D Printing the next generation of Batteries. The internal geometry that produced the best porous electrodes through additive manufacturing was what's known as an interdigitated geometry -- metal prongs interlocked like the fingers of two clasped hands, with the lithium shuttling between the two sides.

PancakeBot is the World's First Pancake Printer. The PancakeBot is the world’s first 3D food printer capable of printing pancakes by automatically dispensing batter directly onto a griddle in a design of the user’s choosing. Designs for printing can be created with the free easy to use downloadable software and then loaded to the PancakeBot 2.0 via and included SD card. Representing an evolution in food-printing technology, PancakeBot 2.0 lets kids and adults express their creativity through food while exploring technology. 3-D Printed Food.

Humans have been making their own stuff for thousands of years, so the makers movement is nothing new. The only thing that's new is the technology and our time in history. Starting in the 20th century, people got use to everything being made for them. And education got dumbed down to create factory workers. But then American corporations exploited cheap labor over seas that drastically reduced the number of jobs that were available. But the worst part was that education is still dumbed down, and millions of jobs are still being shipped to other countries to exploit a low paying labor force. Now machines and automation are increasing, and still education is being dumbed down. Technology has made people realize that they can make their own stuff. But the question is, should people be making their own stuff? Do they need to? And what are the options and choices that might be more productive, efficient and effective and less wasteful? But people are still undereducated. So it's almost impossible for anyone to accurately calculate the actual cost of their actions. 99 percent of people still have no idea of all the cause and effects that happen whenever they do something. Even when people do nothing, they still have no idea of the cause and effects of doing nothing. But we are making some progress. Technology is being democratized, but the most important thing is that knowledge and information also needs to be democratized. That's because only highly educated people can fully utilize technology without waste or abuse, as we can clearly see today. We need to improve education by 1,000 percent so that people fully understand themselves and the world around them. We want people to be independent and be able to survive on their own, but the most important thing is, people need to know how to work together to maximize our efforts, without wasting time, energy and resources. So mass production can still work really well if done right. It's great to make your own stuff and be independent, but everyone knows that we live on a planet with billions of other humans. So we need to understand this fact as well. Being highly educated and skilled would have to include being able to work together and fully utilize our strength in numbers. When everyone becomes an expert and a professional and becomes highly educated, then we will have have a much better world. Now put that in your 3D printer, and let's start going. Live, Learn ,Love and Progress, and then after that, maybe print something useful and see what happens, you never know, or do you?